Introducing a new vision in power line safety

Power line warning & range limiting system

System analytics, alerts, and settings

Keeping you and your equipment safe around overhead power lines

The Voltek 2 alerts you of nearby overhead power lines and then works with you to provide an warning zone to maintain a a safe working distance. The Insight™ Dashboard provides alerts, displays events/analytics, and can even control system settings remotely though the web app.

Detects nearby energized, hazardous power lines

Adjustable sensitivity settings allow the creation of custom warning and "shutdown" zones

Optional Estop, PTO or hydraulic integration to stop or shutdown equipment

Event logging, analytics, push notifications, and settings adjustments via the Insight web app

What We Offer

ALWAYS ON. ALWAYS ALERT.TM

Coming in contact with power lines is, unfortunately, a common risk when operating heavy equipment. The risk of the loss of life and property can be greatly reduced with thorough training, well established procedures and the right safety equipment. The Voltek 2™ and Voltek Insight™ will become valuable assets in you safety program tool belt. Voltek Systems power line warning systems are ALWAYS ON and ALWAYS ALERT™-protecting you and your equipment from power line strikes.

Voltek 2™

Power line warning and range limiting system

HIghlights

-

Detects and alerts you of potentially hazardous nearby powerlines

-

Set warning and shutdown zones to assist in maintaining a safe distance from previously identified power lines

-

Stop or shutdown your equipment with optional Estop/Shutdown integration

-

Progressive warning zone gives operator ample time before Shutdown

-

Remotely monitor and control all button presses, setting changes for and recorded events/alerts with the Insight™ web app (subscription required)

-

Customize alerts received though Insight™ app (i.e. shutdown alerts, systems status changes, etc.)

-

Multiple antenna configurations provide protection for any kind of equipment

-

Intuitive audible and visual alerts are easy to understand and do not interfere with equipment operation

-

Optional limit switch integration to further control and limit range and movement functions on your equipment

-

Multiple accessories available for ultimate monitoring and control

-

Lifetime warranty

-

Designed and manufactured in the USA

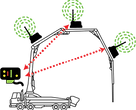

Antenna Configurations

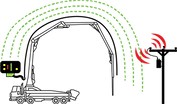

Voltek with linear wire antenna

Voltek with WS (Wireless Sensor)

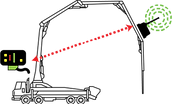

Voltek with linear antenna connected to WS

Voltek with multiple Wireless Sensors

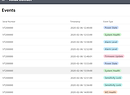

Event logs + alerts + analytics + settings

Insight Dashboard™

HIghlights

-

Remotely view alerts, notifications, system history, from your phone, tablet, or computer

-

Control settings remotely (sensitivity lock, button lock, etc.)

-

Asset management - assign a system to a truck or equipment #, jobsite, etc. for tracking purposes

-

View important alerts in real time via text, push notifications or email

-

Contact Voltek Systems today to learn more!

WS™

Wireless Sensor for Voltek 2

HIghlights

-

Wireless transmission to the Voltek allows for easy and quick installation

-

Durable IP65 enclosure easily attaches to equipment with three powerful magnets (90+lb pull force), strap, or custom mounting brackets

-

Long life battery lasts up to two weeks between charge cycles

-

Works with linear wire antenna for additional coverage

-

Can be used with up to six other sensors

-

External solar panels available for virtually unlimited run time between charges

-

Transmission distance 500' or more (direct line of sight)*

*Transmission distances varies when objects block direct line of sight

Spotter™

Remote Control for Voltek 2

HIghlights

-

View or change settings when access to the Voltek 2 is limited (i.e. concrete pump installation)

-

Durable IP54 enclosure

-

Long life battery lasts up to two weeks between charge cycles

-

remotely activate siren or shutdown (optional) to alert the operator or those nearby of hazards

-

Transmission distance 500' or more (direct line of sight)*

*Transmission distances varies when objects block direct line of sight